Yo-yo Manufacturing

Design for manufacturing is at the root of every yo-yo design in 2.008. The course exposes students to the world of modern manufacturing and teaches management disciplines for determining manufacturing rate, cost, quality, and flexibility. Injection molding was used to produce a total of 50 "Monopoly" themed yo-yos. By taking a more creative approach, my team won the "Most Creative Yo-Yo" award.

Technical Design

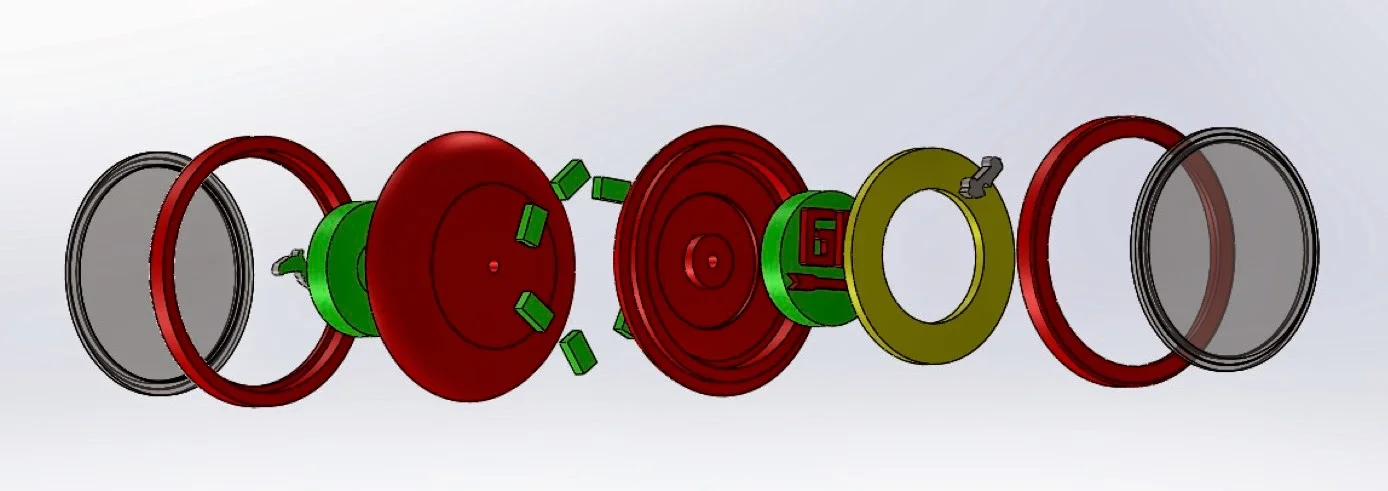

Before beginning the design process, my team brainstormed creative ideas for a yo-yo design. The theme we chose was based on Hasbro's Monopoly game. One side featured Rich Uncle Pennybags with laser cut green acrylic resembling dollar bills. On the opposite side was the iconic "GO" logo, a ring featuring a miniature game board and gray acrylic cut in the shape of a car, one of the game pieces. The covers for both sides of the yo-yo were thermoformed and the rest of the parts were injection molded using polypropylene pellets and two-piece aluminum molds on a 30-ton injection molding machine.

The biggest challenge in designing a yo-yo was determining the appropriate tolerances for every component of the product since all parts were to be assembled using a snap-fit. Additionally all parts were designed with reference to design for manufacturing techniques.

Manufacturing

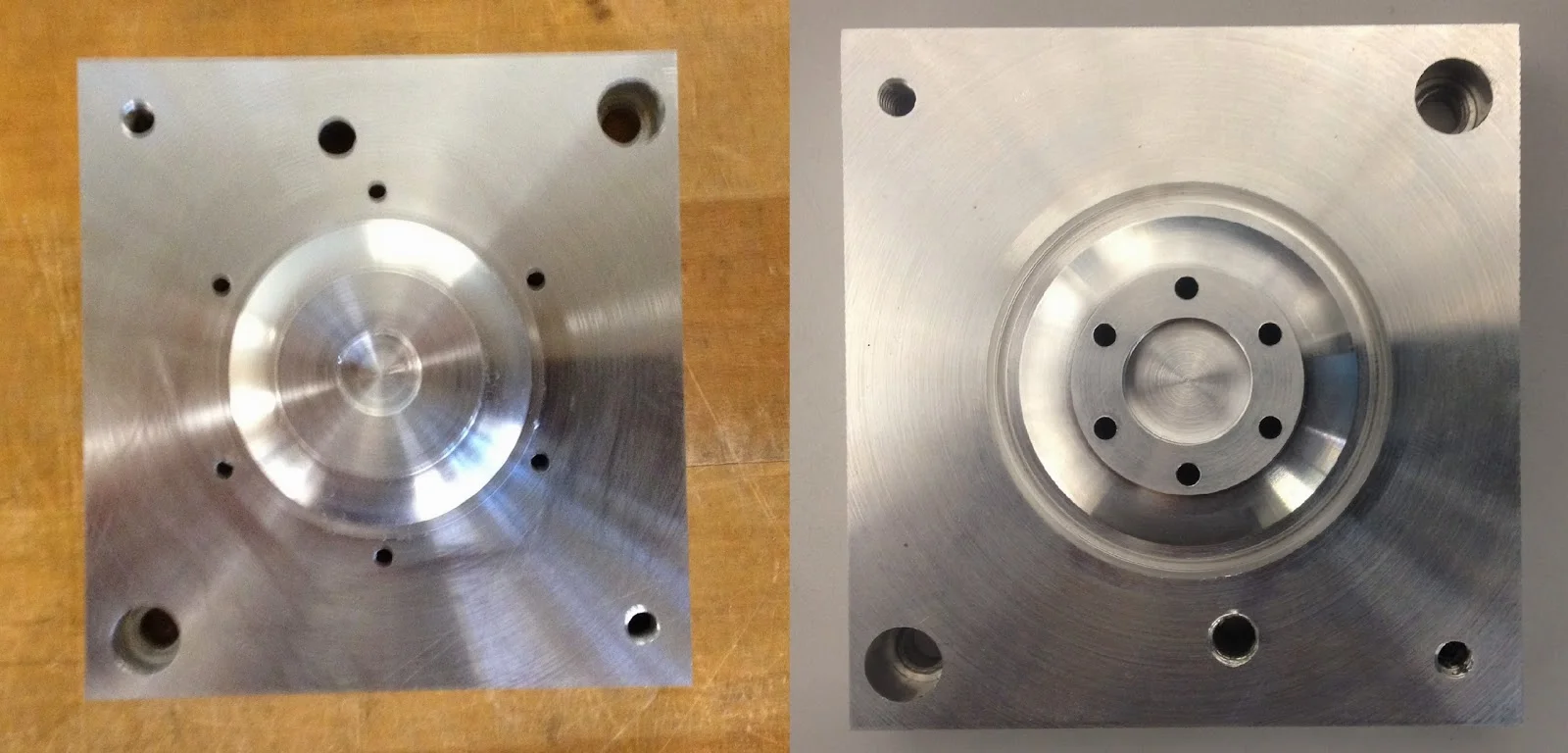

With a finalized design, we proceeded to create the molds to be used in the manufacturing process. This required using SolidWorks drawings to identify all significant dimensions and tolerances and using Mastercam to map toolpaths. The molds were created using a CNC Lathe, an EZ-Trak Mill, and drill press and they underwent several operations to ensure a smooth surface for the molded plastic.

During the first few production runs we faced many challenges which included material sinking, excess flash, and difficulty releasing the part from the mold. To address these issues we optimized the manufacturing process. We increased the clamp force to prevent the creation of any flash, modified the cooling time, and tapered certain features of the mold.

When the appropriate parameters for a successful production run were defined, we began an uninterrupted production of parts for 50 yo-yos followed by the assembly process.

Final Product

Once assembled, the yo-yos from the final production run were tested for functionality. All yo-yos spun well and after evaluation, our team was awarded the "Most Creative Yo-yo" award.

Follow the link below to see a video of the development process of Monopoly themed yo-yo.