Robot competition

One of the most well-known robotic competitions at MIT is the one held in the 2.007 course. At the end of the semester, nearly 100 students participate in the competition. Working individually, students design, build, and test small robots to complete tricky tasks. Taking the knowledge I had developed studying mechanical engineering, I focused on creating a reliable and consistent robot that went out to win 1st place in the competition.

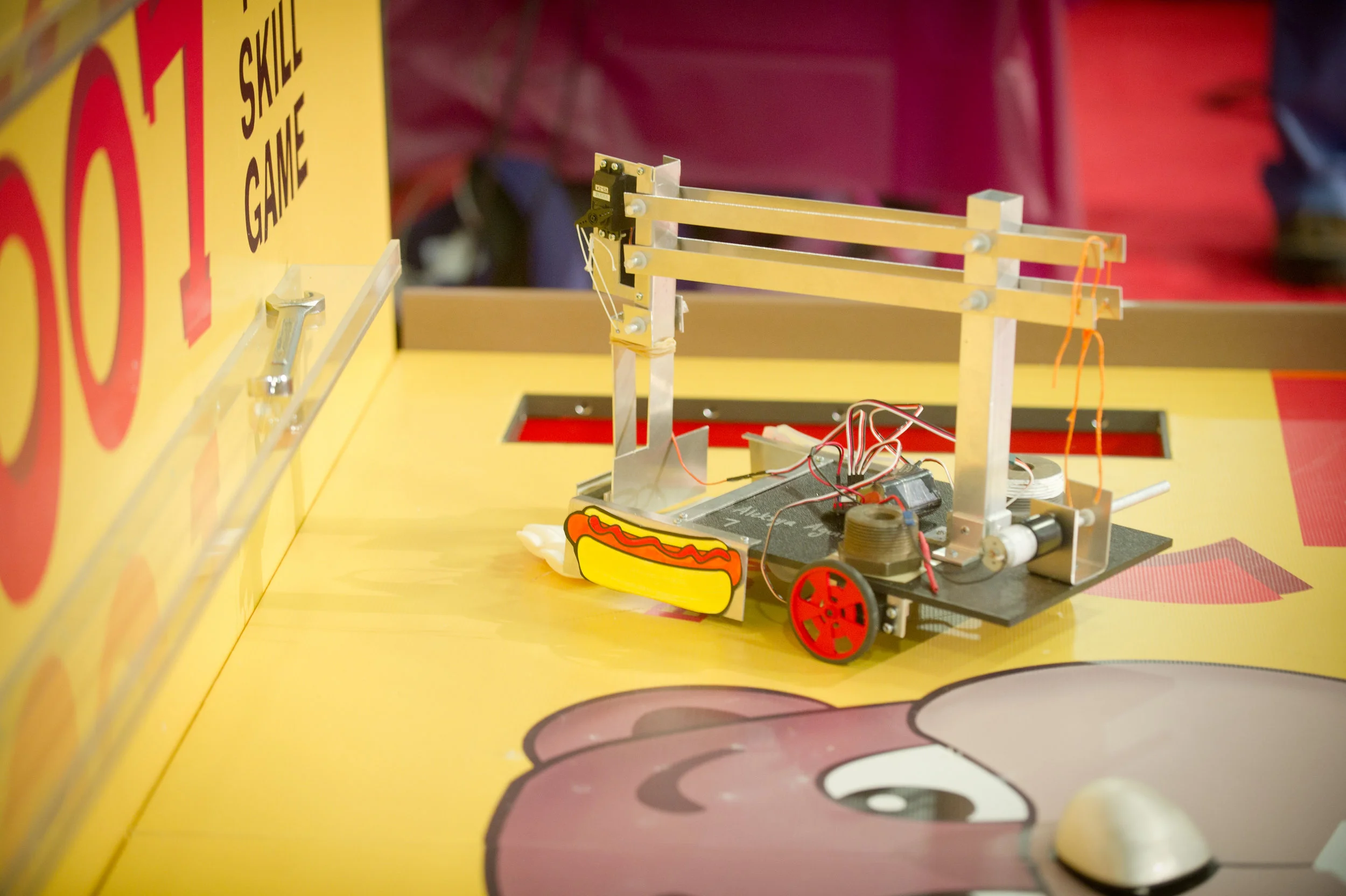

Hot Dog: The Most Loyal of Bots

My overarching goal to win the competition was to design a simple and reliable robot. The first step in designing the robot was identifying the objectives. I focused on attempting and successfully completing two of the available tasks within the allotted two-minutes of each match. These were: (1) removing a wrench from a rectangular pit without touching the metal edges - resulting in a loss of points - and (2) picking up plastic "ribs" and placing them on the shelves for extra points. As for the functional requirements to fulfill these objectives, my robot needed to have the following:

gripping mechanism to hold objects

lifting mechanism to raise the objects

driving mechanism to transport the objects

Having defined the problem and the objectives, I began the concept generation phase. Many ideas were explored during this stage and each plausible concept was analyzed for feasibility with the limited materials available. The concept I chose to proceed with had a base on which all other components were to be mounted. These were two actuated wheels, one small caster wheel in the front, a four-bar mechanism fixed to a rectangular extrusion, a gripper suspended at the end of the parallel bars, and open space for electronics.

I dedicated most of my time to the design and 3D modeling process using SolidWorks on which I could simulate the motion of the robot. The technical design further elaborated on the concept. The base was to be made out of ABS. Two servos mounted onto the bottom of the base actuated the wheels. The four-bar mechanism was implemented as it would contribute only one degree of freedom to the gripper. The height and length of the aluminum base and parallel bars were made such that the gripper could be lowered enough to come in contact with the wrench (the item to be picked up) and raised high enough to place it on the shelf. This smooth motion was controlled by a planetary gear motor that wound up or released a string connected to the parallel bars. The gripper itself had a closed resting position held together with elastic bands providing enough force to carry the wrench and a small servo mounted onto the top edge of the gripper was used to control the motion of the gripper.

I began fabrication when I was sure my design satisfied all functional requirements. Additionally, having a well-defined design resulted in a very smooth fabrication process. Every component was made by me in the workshop. Once assembled, I integrated an Arduino and tested the robot, which I named Hot Dog, using remote control. With time to spare before the day of the competition, I tested Hot Dog several times and optimized accordingly. I added two weights in the rear of the base to move the center of mass further back and increase the friction between the wheels and the ground. I modified the strategy and added foam to the end of the gripper to increase reliability - rather than gripping the wrench at the edges, the foam provided a support on which the wrench could lie as it was raised out of the pit. An aluminum frame surrounding the front of the base served as a special compartment that caught the plastic ribs and maintained them in the perfect orientation to be easily gripped.

Near the end of development, I experimented with making the robot autonomous using Python programming. The autonomous feature worked well and the robot could move by itself along the board, however, its motion was not very precise for picking up the wrench without touching the metal edges of the game board, therefore, for the sake of reliability, I chose to remotely control the robot the day of the competition, after all, each match was only two minutes long and nothing could go wrong in order to take the win.

The Competition

The theme of the competition was an adaptation of Hasbro's Operation board game. The oversized platform featured Tim the Beaver, MIT's mascot, along with different tasks that could be attempted for points. One of the tasks required the extraction of a wrench from a rectangular pit located at Tim's ankle. This task was worth 25 points and hitting the edge of the pit would result in a loss of points. Being able to then place the wrench on a shelf acquired more points. Plastic ribs laying on Tim's torso were also available to either put on a shelf or push into the waste bin, which was another rectangular pit on the board. Each match featured two competitors. Within two-minutes, each robot was to score as many points as possible. There were three rounds total and Hot Dog made it to the final.

Hot Dog's strategy remained consistent throughout the competition. As soon as the time started, went for the wrench. The gripper would lower, secure the wrench, and raise it out of the pit. Hot Dog would then drive to the ribs and push them along its front edge where the ribs remained in an organized position. With the wrench held high and the ribs in front, Hot Dog would drive up to the first shelf where he would place the wrench and with just enough time he would lower the gripper, pick up the ribs, and place them on the shelf as well.

During all three rounds, Hot Dog completed the same tasks in precisely the same order making it the most consistent and reliable robot of them all. Hot Dog's persistence drove him to win 1st place out of 92 competitors, in one of the most renowned robot competitions at MIT.